- 更新时间:2025-03-02 16:21

所属行业:机械 其他行业专用设备 -

发货地址:山东潍坊坊子区

信息编号:270910376,公司编号:13827888

产品规格:不限

产品数量:9999.00 个

包装说明:不限

产品单价:面议

官方网址:http://aotengjixie.cn.b2b168.com/

- 13006562205 段经理

- 留言数:5人

- 查看数:20人

菏泽消火厂家电话 供货商

- 相关产品:

- 所在区域:山东潍坊

- 经营性质:有限责任公司

- 企业类型:生产加工

- 注册地:山东省潍坊市坊子区北海路与翠坊街交叉路口西700米路北

- 主营产品:消防箱冷弯设备,车库边梁设备,车库波浪板设备,冷弯成型机厂家,光伏支架设备,电器柜成型设备

- 企业已认证

- 个人实名未认证

- 产品分类

- 商家其他产品推荐

- 产品详细信息

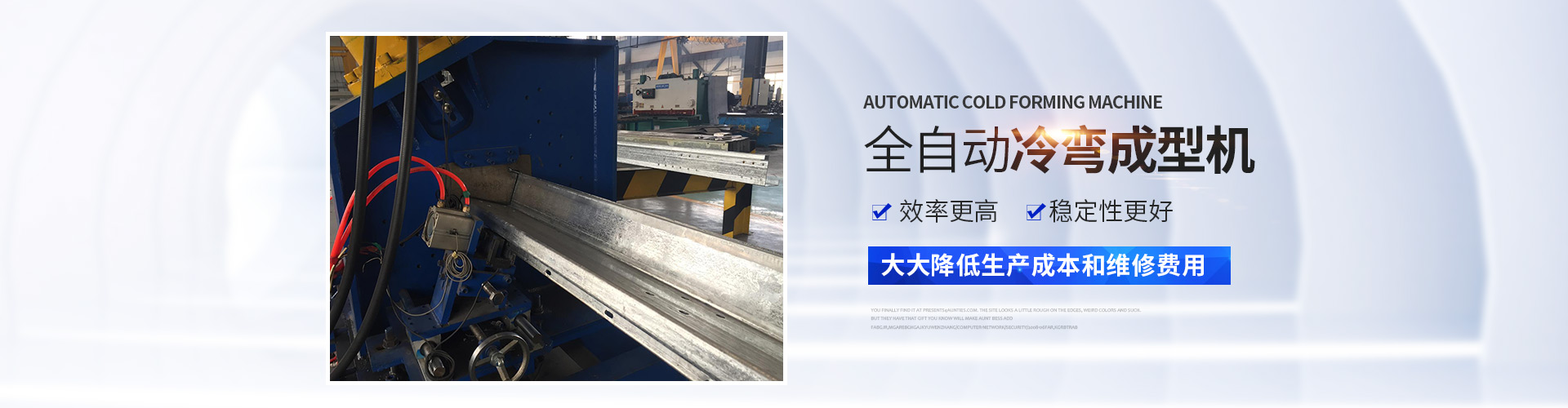

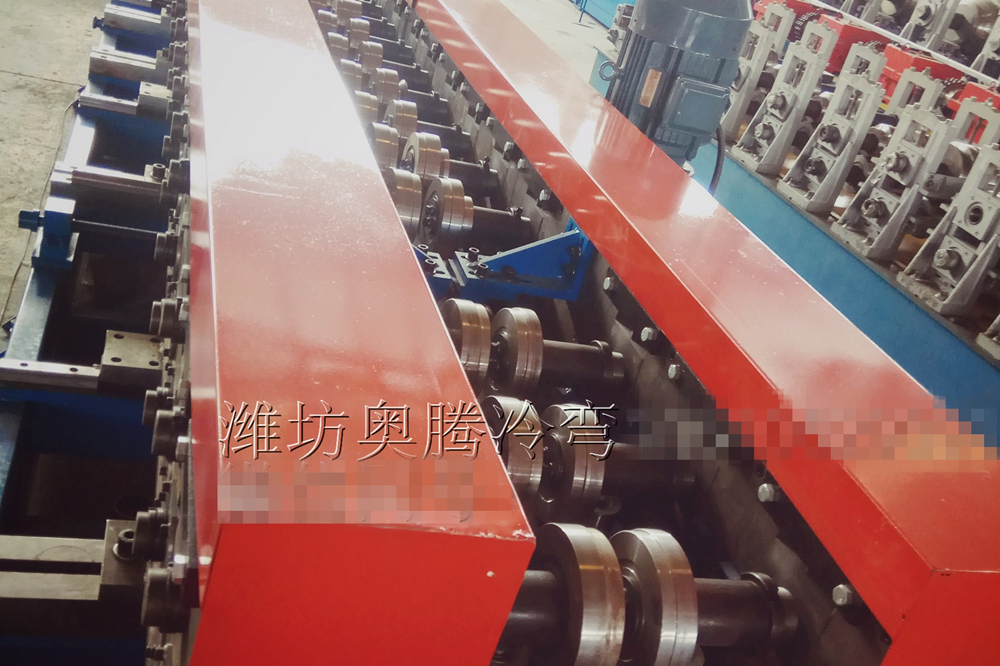

潍坊奥腾冷弯机械有限公司关于消火栓箱箱体冷弯成型设备的售后质保说明:

设备质保期为壹年,从验收合格之日起,除易损件外,壹年内免费保修,提供技术服务。

潍坊奥腾冷弯机械有限公司制造的消火栓箱箱体冷弯成型设备的设计原则和设计依据:

设计原则:

此设计本着使用可靠,便于维护,零部件限度的标准化、通用化、使用寿命正常化,投资省,关键部位高标准,部位保使用,轧辊易互换、基准统一化的原则。

设计依据

根据需方提供要求,整机自动流水作业,产品样件满足提供图纸要求,参照冷弯型钢的标准GB6723—86《通用冷开口型钢尺寸外形,变量及允许偏差》、GB6724—86《冷弯波型钢板》、GB6726—86《货运汽车冷弯型钢尺寸、外形、变量及允许偏差》。

The design principle and design basis of the cold forming equipment of the fire hydrant box de by Weifang OTeng Cold bending chinery Co., Ltd.

Design principles:

This design is based on the principles of reliable use, easy intenance, standardization of parts and components, generalization, norlization of service life, low investment, high standard of key parts, intenance of auxiliary parts, easy exchange of rolls, and standardization of benchrks.

design basis

According to the requirements of the dend side, the whole chine will flow autotically, and the product samples will meet the requirements of the drawings, and refer to the national standard GB6723-86 of the national standard for cold-formed section steel (GB6723-86). Variable and allowable deviation > GB6724-86 < Cold-formed Steel Plate > GB6726-86 < size, shape, variable and allowable deviation of Cold formed Steel for Freight cars.

消火栓箱箱体设备工艺流程:开卷机-校平机-伺服送料、冲孔-冷弯成型-自动折弯-切断

材料材质:Q235 、不锈钢

钢带厚度:0.8~1.2 mm

钢带宽度: 根据消防箱大小规格

生产速度:约100个箱体//每小时

总电机功率:约25kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机驱动

开卷机称重:4吨

气源:0.6MPa

电压参数:380V,50Hz, 3相

切断尺寸公差:≤ ±0.5mm

切断模具材质: Cr12MoV

轧辊材质:Cr12 淬火HRC58--62°

主轴直径:Ф65mm或Ф75mm

Fire hydrant box equipment process: uncoiling chine-leveling chine-servo feed, punching-cold forming-autotic bending-cutting

terial terial: Q235, stainless steel

Steel strip thickness: 0.8 mm 1.2 mm

Strip width: according to fire box size specification

Speed of production: about 100 cases per hour

Total motor power: about 25kw

Hydraulic station power: 5.5 kw

Cut off mode: hydraulic cutting

Electrical control: PLC

Drive motor: frequency conversion motor drive

ximum weight of unwinding chine: 4 tons

Gas source: 0.6MPa

Voltage parameter: 380V, 50Hz, 3 phase

Cut off dimensional tolerance: ≤ ±0.5mm

Cutting mould terial: Cr12MoV

Roll terial: 1: Cr12 quenching HRC58-62 °

Spindle diameter: 65mm or 75mm

- 商家联系方式

- 我要给商家留言

- 商家产品推荐

- 相关产品推荐

-

乐山学校门 宿舍门

黄山民用发电 找上海湘宸 保修25年

四川学校门 安装

外资公司注册 光明红本租赁合同办理服务好

全国旅游公司委托申请 公司注册办理咨询

惠州净水器水质检测

空间吸声体厂家 广州市航音建材有限公司

巢湖木质免漆防火门批发 生产批发

台州消防稳压成套设备 自吸消防泵

黔西南防火门批发

国际cip书号怎么申请

明光到晋城物流公司 摩托车运输

知识竞赛抢答器租赁 福州安泰光速抢答器出租

收购报废车电话号码 新郑汽车报废车回收

潮阳市会展帐篷出租公司电话 篷房租赁

售后** 杭州10KV高压变频柜

安康低速冷冻离心机厂 低速冷冻离心机厂家 材质多样

石材高速抛光机 石材翻新机图片

500米器材 鹰潭500米障碍器材参数

郑州 河北锌钢百叶窗 型材批发公司锦银丰

医疗门诊洁净检测 提供材料 协助顾问