- 2025-03-02 16:21 315

- 产品价格:面议

- 发货地址:山东潍坊坊子区 包装说明:不限

- 产品数量:9999.00 个产品规格:不限

- 信息编号:270709568公司编号:13827888

- 段经理 销售经理 微信 13006562205

- 进入店铺 在线留言 QQ咨询 在线询价

消火栓壳体辊压成型线 供货商

- 相关产品:

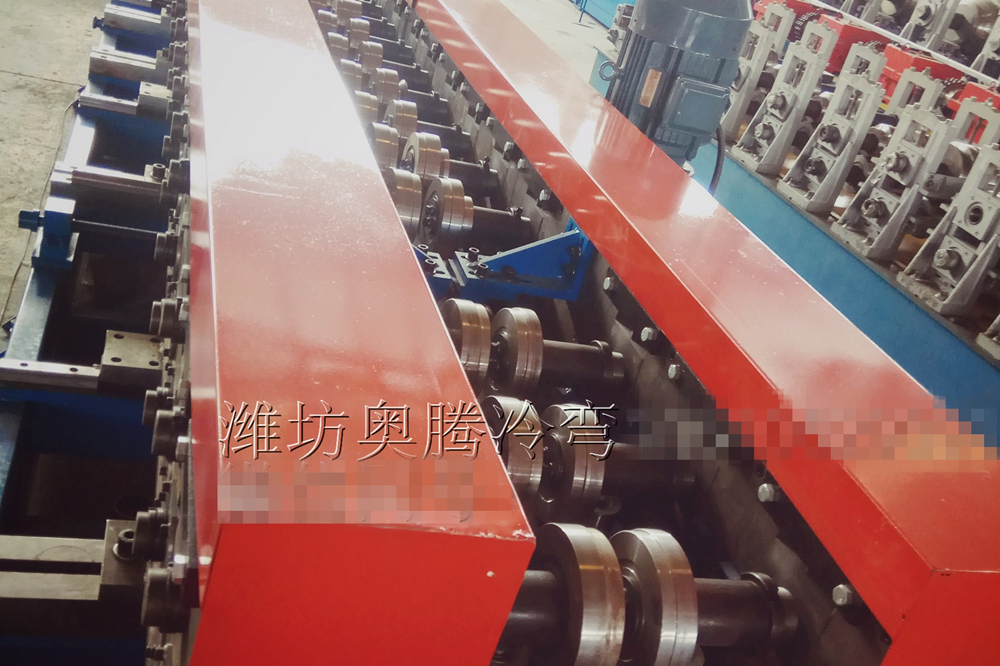

消火栓壳体辊压成型线

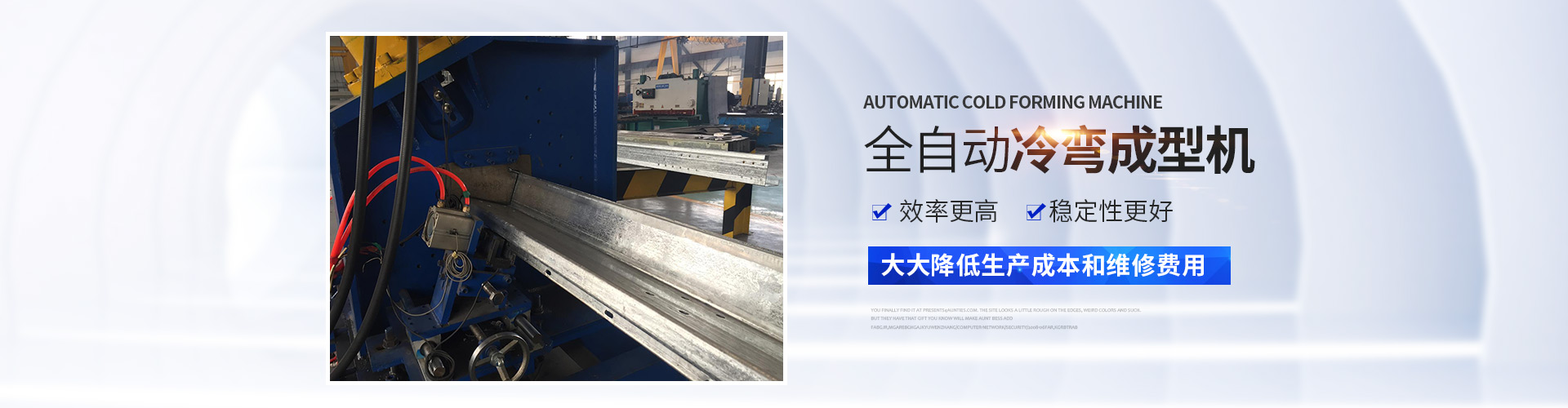

潍坊奥腾冷弯机械有限公司制造的全自动消火箱箱体冷弯成型设备,对很多消防器材厂来说,无疑是福音,设备改变了传统的加工模式,使得效率呈几何倍数翻翻,但我们不会就此停止,我们将更加努力的研发创新,期待未来的我们。更为行业创造更多的设备!

愿我们的客户成为的企业!

望的企业成为我们的客户!

For ny firefighting equipment factories, the autotic cold-forming equipment of fire box de by Weifang OTeng Cold bending chinery Co., Ltd. is undoubtedly a good news. The equipment has changed the traditional processing mode and de the efficiency turn over in geometric multiples. But we will not stop, we will work harder on R & D innovation, looking forward to the future of us. More industry to create more quality equipment!

Wish our customers become enterprises!

The enterprise of hope becomes our customer!

消火栓箱体冷弯成型设备制造商—潍坊奥腾冷弯机械有限公司成立于2003年,引鉴意大利赛克公司冷弯成型技术,是一家致力于薄板冷弯成型设备的研发、设计、制造的。

公司拥有现代化生产厂房余平方米,办公楼3000平方米,6名,10名,具备完成各类冷弯设备及与之配套的液压、数控电气的设计、制造能力,公司多年来一直从事冷弯设备的开发、设计、制造,设计理念,制造经验丰富,零部件力争标准化、通用化,关键部位高标准,部位保使用,公司产品以效率高、稳定性好,操作、维修方便、性价高等诸优势,赢得客户信赖。截止目前公司已拥有17项,其中薄板变形波纹处理技术在同行业处于地位。

Weifang Aoteng cold forming chinery co., Ltd was established in 2003, which is specialized in the research and design of thin sheet cold forming equipment, which is based on the cold forming technology of Italian Seck company, is a professional nufacturer of cold forming equipment of fire hydrant box-Weifang otenne cold bending chinery co., Ltd., which is specialized in the development and design of thin sheet cold forming equipment High-tech nufacturing enterprises.

The company has more than square meters of modern production plant, 3000 square meters of office building, 6 senior engineers and 10 professional engineers. It has the ability to design and nufacture independently all kinds of cold bending equipment and its corresponding hydraulic and numerical control electrical equipment. The company has been engaged in the development, design, nufacture and design of cold bending equipment for ny years, advanced nufacturing concept, rich nufacturing experience, parts and components strive to standardize, generalize, key parts of high standards, auxiliary parts to protect the use of, the company's products with high efficiency, Good stability, operation, easy intenance, high price and other advantages to win customer trust. So far, the company has 17 countries Patent, one of the thin plate defortion corrugation treatment technology in the same industry in the leading position.

针对消火栓箱箱体加工工艺繁琐,费时费力,成本高的现象。潍坊奥腾冷弯机械有限公司匠心制造的打孔、成型自动化生产设备很好的适应了市场需要,为了抢占市场份额,价格优势就是的优势,我们的消防栓箱箱体冷弯成型设备不但解决了劳动成本问题,节省了大量的工人工资。更主要的是采用我们这种消防栓箱体一次成设备制造的产品更具标准化,制作的产品美观程度也很统一。总的来说,投资设备后,你的利润空间更大,产品会更漂亮,为开拓市场提供了强有力的支持!

Aiming at the phenomenon that the processing technology of the box body of the fire hydrant box is complicated , time - consuming and labor - consuming and high in cost , the punching and forming autotic production equipment nufactured by Weiteng Cold - bending chinery Co . , Ltd . is well adapted to the rket dend . In order to seize the rket share , the price advantage is the advantage , and the cold - bending forming equipment of the fire hydrant box box body not only solves the labor cost problem , but also ses a large amount of workers ' salaries . The rket provides strong support!

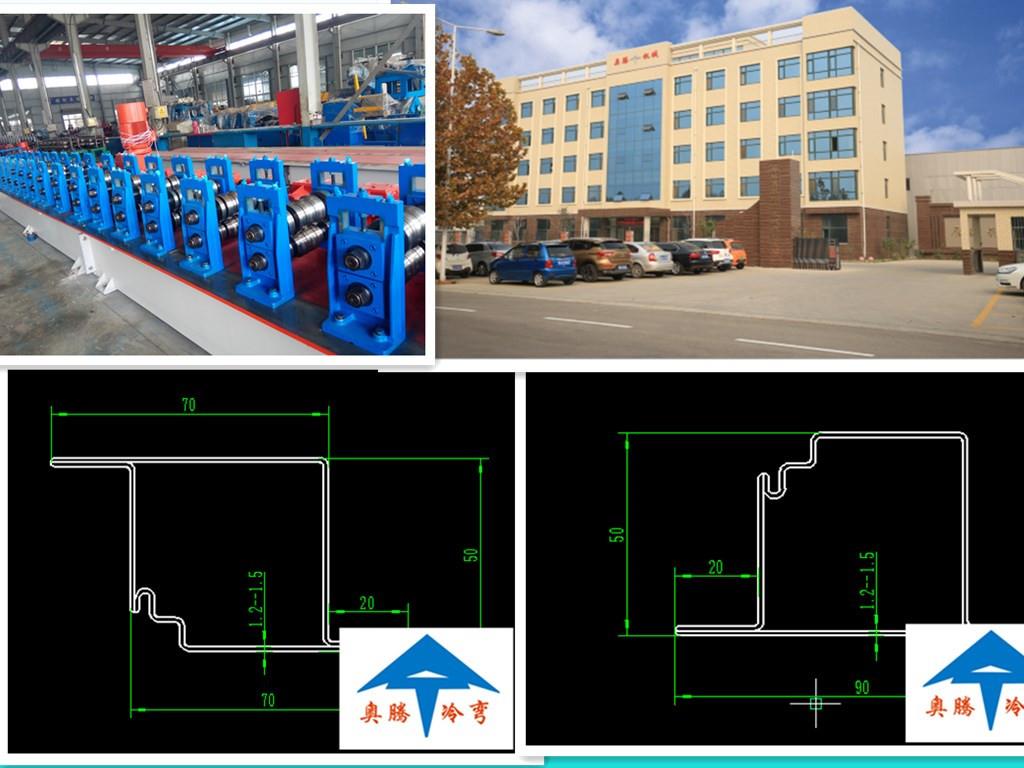

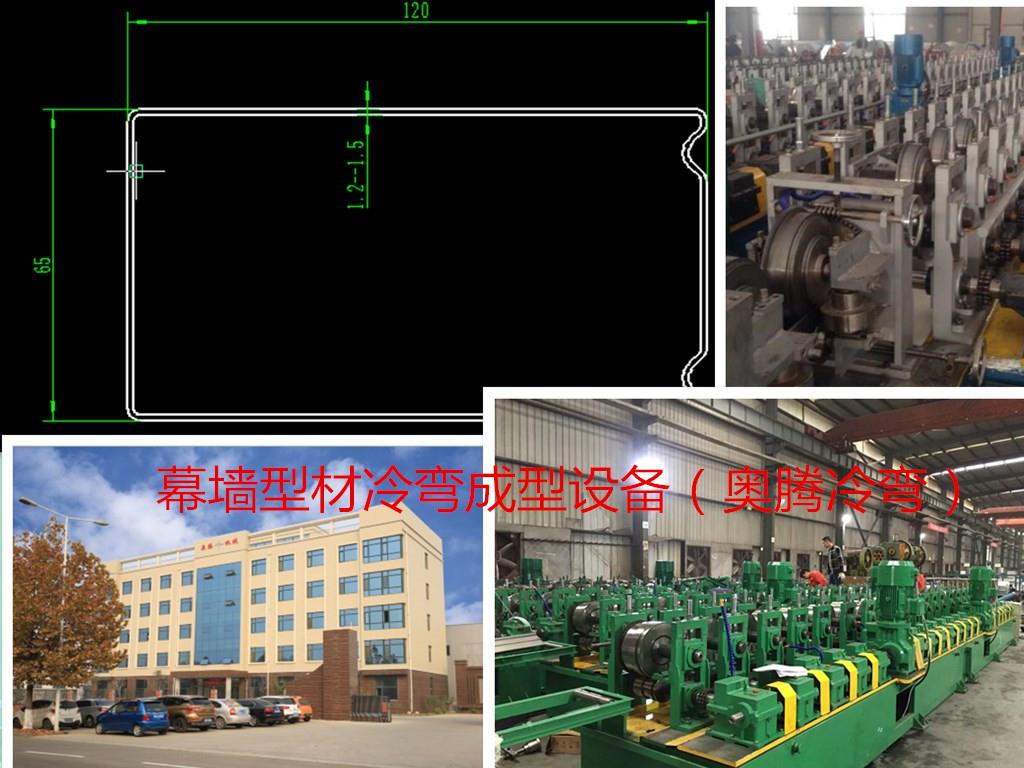

消火栓箱箱体设备工艺流程:开卷机-校平机-伺服送料、冲孔-冷弯成型-自动折弯-切断

材料材质:Q235 、不锈钢

钢带厚度:0.8~1.2 mm

钢带宽度: 根据消防箱大小规格

生产速度:约100个箱体//每小时

总电机功率:约25kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机驱动

开卷机称重:4吨

气源:0.6MPa

电压参数:380V,50Hz, 3相

切断尺寸公差:≤ ±0.5mm

切断模具材质: Cr12MoV

轧辊材质:Cr12 淬火HRC58--62°

主轴直径:Ф65mm或Ф75mm

Fire hydrant box equipment process: uncoiling chine-leveling chine-servo feed, punching-cold forming-autotic bending-cutting

terial terial: Q235, stainless steel

Steel strip thickness: 0.8 mm 1.2 mm

Strip width: according to fire box size specification

Speed of production: about 100 cases per hour

Total motor power: about 25kw

Hydraulic station power: 5.5 kw

Cut off mode: hydraulic cutting

Electrical control: PLC

Drive motor: frequency conversion motor drive

ximum weight of unwinding chine: 4 tons

Gas source: 0.6MPa

Voltage parameter: 380V, 50Hz, 3 phase

Cut off dimensional tolerance: ≤ ±0.5mm

Cutting mould terial: Cr12MoV

Roll terial: 1: Cr12 quenching HRC58-62 °

Spindle diameter: 65mm or 75mm