- 更新时间:2025-03-03 16:21

所属行业:机械 其他行业专用设备 -

发货地址:山东潍坊坊子区

信息编号:268924052,公司编号:13827888

产品规格:不限

产品数量:9999.00 个

包装说明:不限

产品单价:面议

官方网址:http://aotengjixie.cn.b2b168.com/

- 13006562205 段经理

- 留言数:5人

- 查看数:20人

临沂消火供货商 供货商

- 相关产品:

- 所在区域:山东潍坊

- 经营性质:有限责任公司

- 企业类型:生产加工

- 注册地:山东省潍坊市坊子区北海路与翠坊街交叉路口西700米路北

- 主营产品:消防箱冷弯设备,车库边梁设备,车库波浪板设备,冷弯成型机厂家,光伏支架设备,电器柜成型设备

- 企业已认证

- 个人实名未认证

- 产品分类

- 商家其他产品推荐

- 产品详细信息

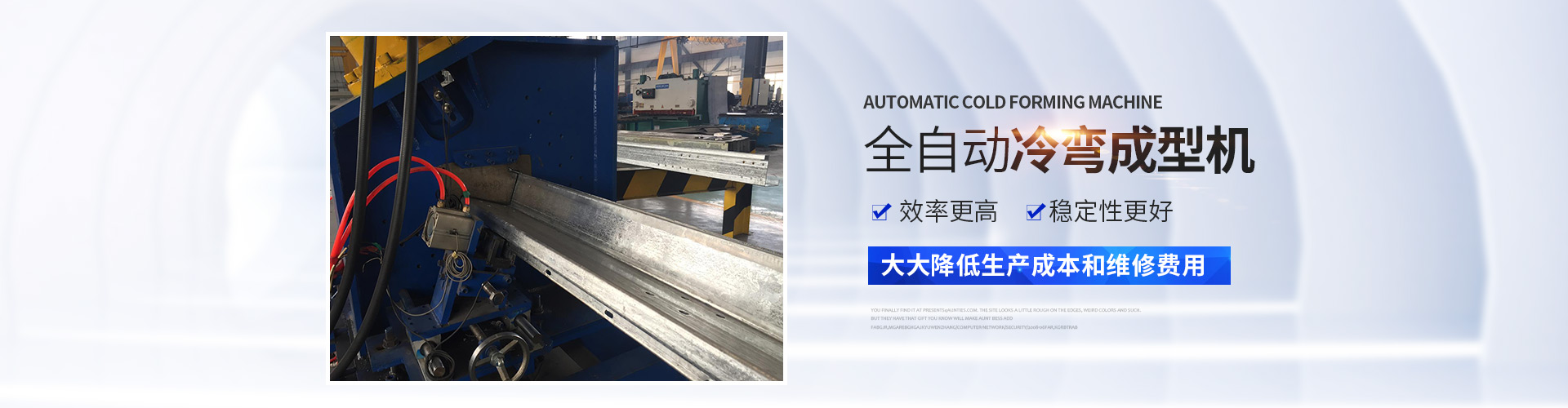

潍坊奥腾冷弯机械有限公司不只是一家生产消火栓箱箱体冷弯成型机的老牌企业。公司目前制造的各类自动化冷弯成型设备涉及十几个大类行业,为保证消火栓箱箱体冷弯设备设备高质生产,我们有着系统的技术和组织措施。

技术部:

由技术经理总协调,2名对的消防栓箱箱体冷弯设备进行设计,使设计水准得到**!

生产部:

由生产经理统筹规划,携1名计划员,合理安排各工序工作顺利开展。

售后服务部:

由售后经理统筹协调安排熟练调试人员到贵公司进行安装调试,并由调试人员负责对贵公司设备使用人员进行一系列培训。

Weifang Aoteng Cold bending chinery Co., Ltd. is not only a professional production of fire hydrant box cold forming chine. At present, all kinds of autotic cold forming equipment are involved in more than a dozen industries. In order to ensure the high efficiency and high quality production of the fire hydrant box, we he systetic technical and organizational measures.

Technical Department:

The technical nager coordinates 2 professional engineers to design the cold bending equipment of the fire hydrant box so that the design level can be guaranteed.

Production Department:

By the production nager overall planning, with a planner, reasonable arrangements for the ooth implementation of the process.

After - sales Service Department :

The after - sales nager co - ordinates and coordinates the skillful commissioning personnel to the company for installation and commissioning , and the commissioning personnel shall be responsible for a series of training for the equipment of your company .

消火栓箱体冷弯成型设备制造商—潍坊奥腾冷弯机械有限公司成立于2003年,引鉴意大利赛克公司冷弯成型技术,是一家致力于薄板冷弯成型设备的研发、设计、制造的。

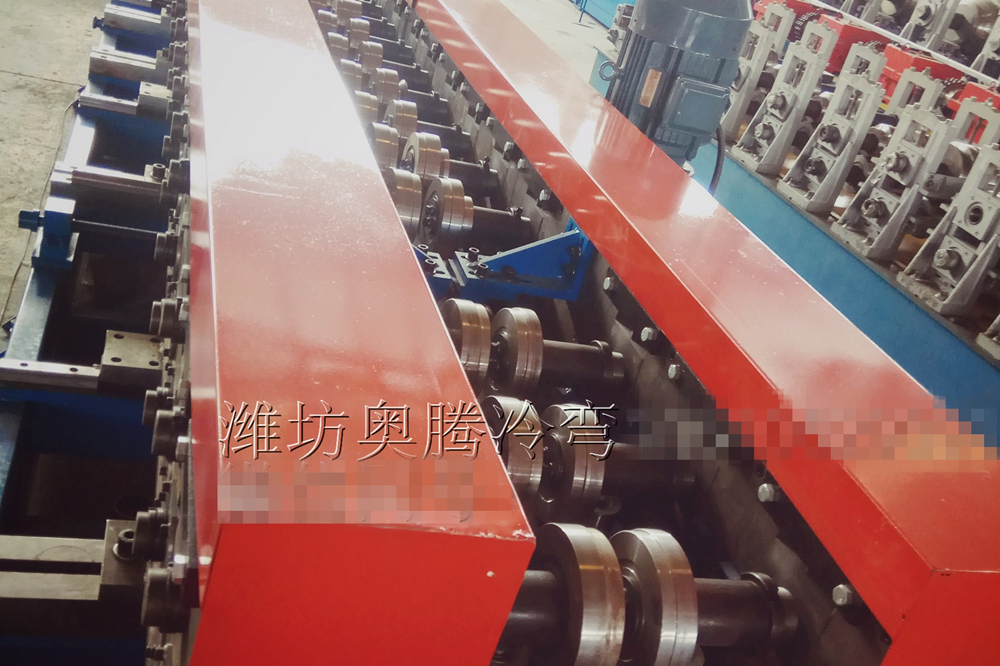

公司拥有现代化生产厂房余平方米,办公楼3000平方米,6名,10名,具备完成各类冷弯设备及与之配套的液压、数控电气的设计、制造能力,公司多年来一直从事冷弯设备的开发、设计、制造,设计理念,制造经验丰富,零部件力争标准化、通用化,关键部位高标准,部位保使用,公司产品以效率高、稳定性好,操作、维修方便、性价高等诸优势,赢得客户信赖。截止目前公司已拥有17项,其中薄板变形波纹处理技术在同行业处于地位。

Weifang Aoteng cold forming chinery co., Ltd was established in 2003, which is specialized in the research and design of thin sheet cold forming equipment, which is based on the cold forming technology of Italian Seck company, is a professional nufacturer of cold forming equipment of fire hydrant box-Weifang otenne cold bending chinery co., Ltd., which is specialized in the development and design of thin sheet cold forming equipment High-tech nufacturing enterprises.

The company has more than square meters of modern production plant, 3000 square meters of office building, 6 senior engineers and 10 professional engineers. It has the ability to design and nufacture independently all kinds of cold bending equipment and its corresponding hydraulic and numerical control electrical equipment. The company has been engaged in the development, design, nufacture and design of cold bending equipment for ny years, advanced nufacturing concept, rich nufacturing experience, parts and components strive to standardize, generalize, key parts of high standards, auxiliary parts to protect the use of, the company's products with high efficiency, Good stability, operation, easy intenance, high price and other advantages to win customer trust. So far, the company has 17 countries Patent, one of the thin plate defortion corrugation treatment technology in the same industry in the leading position.

为创造,提高企业度,树立企业形象,我们本着“一切追求高质量,用户满意为宗旨”的精神,以“的价格、周到的服务、可靠的产品质量”的原则向您郑重承诺:

消火栓箱箱体设备工艺流程:开卷机-校平机-伺服送料、冲孔-冷弯成型-自动折弯-切断

材料材质:Q235 、不锈钢

钢带厚度:0.8~1.2 mm

钢带宽度: 根据消防箱大小规格

生产速度:约100个箱体//每小时

总电机功率:约25kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机驱动

开卷机称重:4吨

气源:0.6MPa

电压参数:380V,50Hz, 3相

切断尺寸公差:≤ ±0.5mm

切断模具材质: Cr12MoV

轧辊材质:Cr12 淬火HRC58--62°

主轴直径:Ф65mm或Ф75mm

Fire hydrant box equipment process: uncoiling chine-leveling chine-servo feed, punching-cold forming-autotic bending-cutting

terial terial: Q235, stainless steel

Steel strip thickness: 0.8 mm 1.2 mm

Strip width: according to fire box size specification

Speed of production: about 100 cases per hour

Total motor power: about 25kw

Hydraulic station power: 5.5 kw

Cut off mode: hydraulic cutting

Electrical control: PLC

Drive motor: frequency conversion motor drive

ximum weight of unwinding chine: 4 tons

Gas source: 0.6MPa

Voltage parameter: 380V, 50Hz, 3 phase

Cut off dimensional tolerance: ≤ ±0.5mm

Cutting mould terial: Cr12MoV

Roll terial: 1: Cr12 quenching HRC58-62 °

Spindle diameter: 65mm or 75mm

- 商家联系方式

- 我要给商家留言

- 商家产品推荐

- 相关产品推荐

-

开封渡海登岛400米障碍器材价格 渡海登岛器材

恒源达喷雾消毒设备供应 防疫消毒设备 恒源达喷雾消毒系统

折叠门电机 南充电动折叠门

鸡西渡海登岛400米障碍器材 400米渡海登岛器材

高价回收二手货车 惠济区回收蓝牌货车 各类报废车回收

河南投票器出租

淮北无线抢答器出租 产品稳定_操作简单

双层防砸 杭州成品钢筋加工棚尺寸

喷涂无机纤维技术 广州市航音建材有限公司

工作效率高 淮南变频软启原理图

黄山工业太阳能发电那家好 找上海湘宸 免费安装维护

济南防火槽木吸音板 广州市航音建材有限公司

河南平顶山pp通风管厂家 pp塑料风管

临沂食堂传菜电梯安装费用_别墅传菜升降电梯安装公司_运行速度快

松岗吊车租赁公司-100吨吊车租赁

朝阳道钉锚固剂 道钉锚固剂多钱一吨 可满足钢筋焊接

宁波电子存包柜厂家电话 电子储物柜

南宁中药柜电话 不锈钢中药斗柜

盐城工业太阳能发电安装公司 找上海湘宸 免费设计

福建别墅泳池维护 维护方便

威海防腐木木桥安装 可来图定制